MME Graduate Researcher awarded the Dr. Andy Nieto Memorial Graduate Scholarship for Excellence in Materials Science and Engineering

- Post by: Aime Fernandez

- October 23, 2023

- Comments off

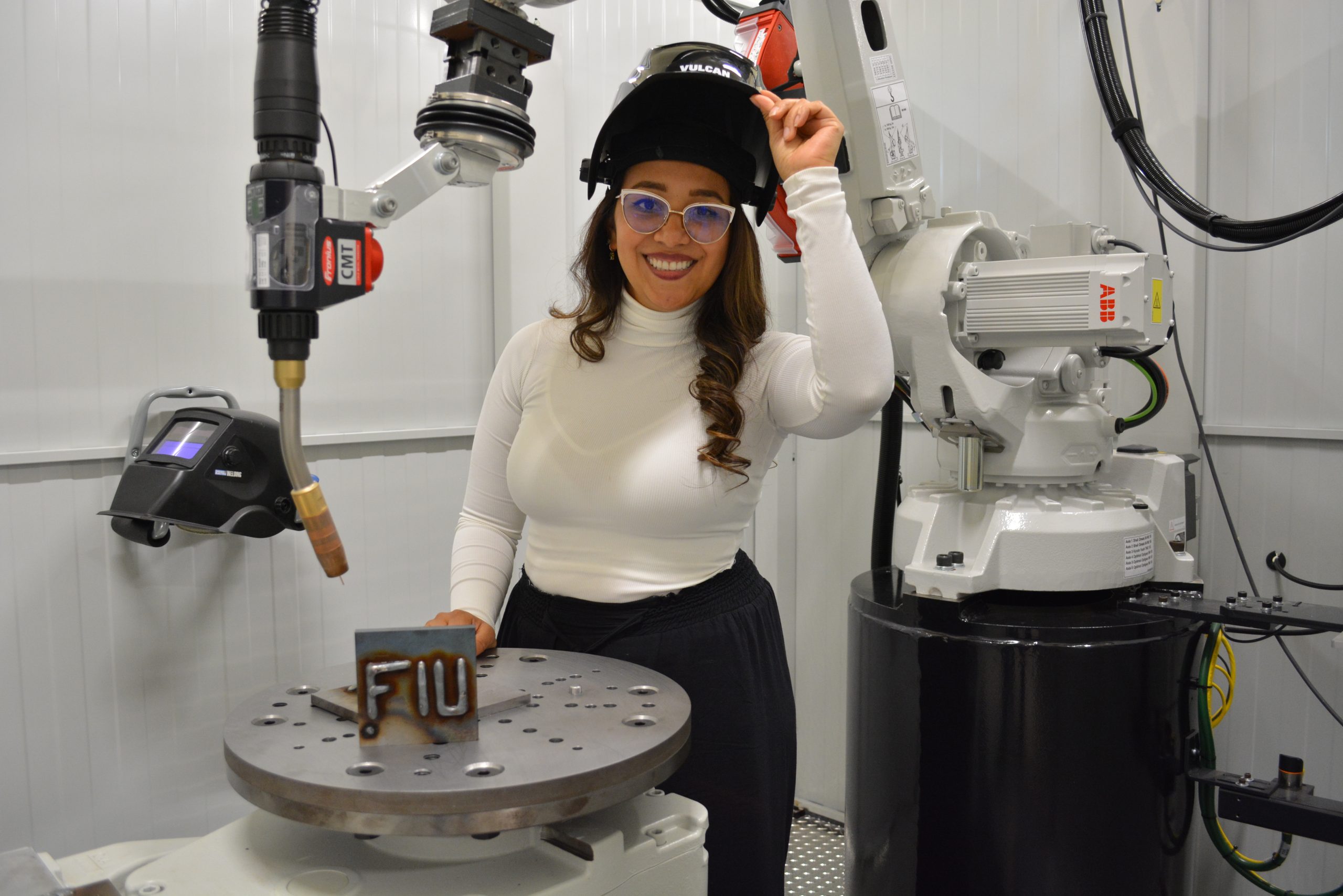

Congratulations to Graduate Researcher, Blanca Palacios for being awarded the Dr. Andy Nieto Memorial Graduate Scholarship for Excellence in Materials Science and Engineering! As a Ph.D. student, a Latin American woman in STEM, wife, and mother, Blanca is profoundly honored to be the first recipient of this scholarship.

The scholarship was established by Dr. Andy Nieto’s wife, Dr. Richa Agrawal in 2023 to honor his memory and support graduate students in the field of material science of engineering as well as recognize journal article that have made a significant impact.

Dr. Andy Nieto graduated from Florida International University with a Masters in Materials Science in 2013, working for FIU as a Research Engineer. Later attending UC Davis for his Ph.D. and graduating in 2016 where he started working as a Postdoctoral fellow for the U.S. Army Research Laboratory. Focusing on advanced characterization of propulsion materials and materials solutions to challenges within turbomachinery applications and sciences. In 2018, he became an Assistant Professor for the Naval Postgraduate School department of Mechanical and Aerospace Engineering (MAE). His wife, Dr. Richa Agrawal also graduated from Florida International University with a Ph.D. in Materials Science and Engineering.

Blanca’s paper, “Role of structural hierarchy on mechanics and electrochemistry of wire arc additive manufactured (WAAM) single phase titanium” addresses the gaps in understanding additive manufacturing of titanium components for marine applications, emphasizing the relationship between material structure, mechanics, and electrochemistry. Her investigation revealed a single-phase α-Ti monolithic structure in WDED-produced cp-Ti with lack observable deposition tracks and interfaces. This groundbreaking discovery opens new horizons for homogeneous, large-scale additive manufacturing. On the other hand, the exploration of hardness and mechanical properties resulted in a uniform distribution of microhardness along the layer-by-layer build-up direction. With an average hardness of 1.6 GPa, this finding represents a significant advancement, achieving approximately 80% of the hardness of conventionally cast cp-Ti. This study also uncovered an exceptional degree of corrosion resistance exhibited by the WDED-produced cp-Ti. With a corrosion rate of only 80 × 10^-5 mm per year, this material surpasses other additive-manufactured titanium alloys by nearly 50%.

This study represents a significant stride in the field of materials science and engineering, particularly within the realm of wire arc direct energy deposition of commercially pure titanium. The novel insights unveiled hold the potential to revolutionize large-scale additive manufacturing processes. These discoveries bear promise for various industries and signify substantial progress towards technological advancement.