Spark Plasma Sintering Laboratory

The Spark Plasma Sintering (SPS) lab is a state-of-the-art facility equipped with advanced machinery for consolidating materials using rapid heating and high pressure. This method employs Pulsed DC current and simultaneous mechanical pressure, eliminating the need for pre-forming and binders. Our lab specializes in utilizing the SPS technique to produce high-density materials with tailored microstructures and enhanced mechanical properties. The versatility of SPS extends to the processing of various materials, including metallic, ceramic, intermetallic, polymer, and composite powders.

Tools

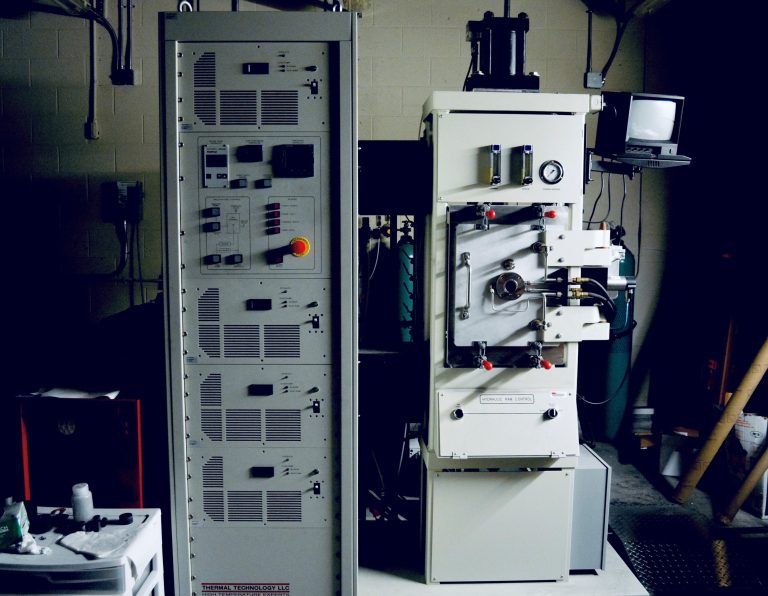

Spark Plasma Sintering

Spark Plasma Sintering (Model: SPS 10-4 Advanced Technology, Santa Rosa, CA, USA) is a rapid sintering process

characterized by a controllable level of densification.

Features/Specifications:

Force: 20,000 lbs

Pressing Ram: 4 in Stroke

Max Temperature: 2200 ℃

Electrical Output: 10V/ 4,000 amps Pulsed DC (MAX)

Environment: Vacuum, and Ar

Ultimate Vacuum: 10-3 Torr Range

Die Size: Ø 10 mm, 20 mm and 40 mm

Ongoing Research Projects

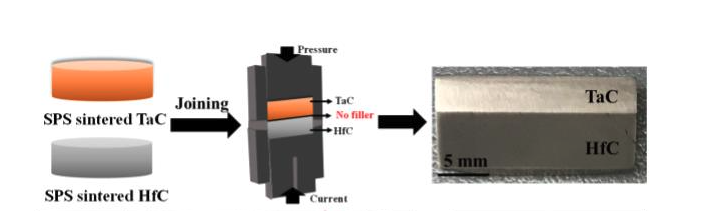

Joining of Ultra-High Temperature Ceramics

The potential of various new modifications has broadened usability of SPS from merely a densification tool to the fabrication of complex-shaped components, functionally gradient materials, joining of materials, and porous filter materials for real-life applications. Our group is currently involved in processing of High-entropy ultra-high temperature ceramics (HEUHTCs); Non-oxide ceramic foams via pressureless SPS; Joining of dissimilar materials including metals, UHTCs and HE-UHTCs, Layered Structure of UHTC decorated C-fibers, Boron Nitride Nanotubes (BNNT) reinforced composites and 2D materials Composite.

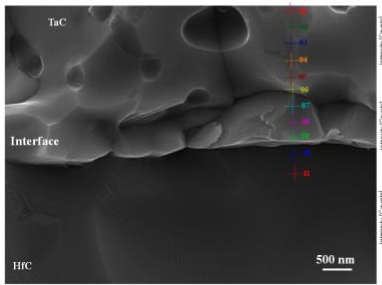

In this study, we choose to investigate a new method of rapidly joining pre‐sintered TaC and HfC ceramics without any filler material using SPS technique. A well‐bonded TaC–HfC interface was observed with no apparent cracking and porosity at the joint. The joining mechanisms were predominantly driven by solid‐state diffusion and localized plastic deformation. After joining, we utilize advanced characterization techniques to carefully evaluate their mechanical properties.