Cold Spray and Rapid Deposition (ColRAD) Laboratory

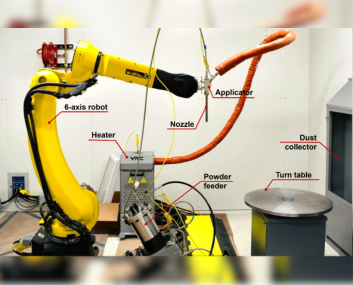

The Cold Spray and Rapid Deposition (ColRAD) Lab is a pioneering research facility dedicated to advancing cold spray technology. With a primary focus on powder processing, parameter development, and deposit consolidation, its research efforts span various applications. Leveraging its expertise, the lab explores a wide range of materials including polymers, ceramics, and metals for industrial and technological advancements. Its advanced capabilities in material consolidation make it a valuable resource for repairing components, developing coatings, and additive manufacturing of near-net-shaped complex parts

Tools

High-Pressure VRC Raptor Cold Spray System

The VRC Raptor is a high-pressure cold spray system with advanced features that establish it as a versatile and efficient solution for a wide range of applications in coatings and additive manufacturing.

Features/Specifications:

Max system pressure: 100 to 1000 PSI

Gas type: Helium, Nitrogen, Compressed air Max gas flow: 2500 SLM

Max heat temperature: 800 °C

Max applicator temperature: 650 °C

Powder feed flow: 25 to 450 SLM

Powder feed rate: 0.5 to 12 rpm

Cold Spray System CSM 108.2

This portable, low-cost cold spray system, manufactured by Dymet , operates at low pressure. Primarily utilizing air as the carrier gas, it demonstrates the capability to consolidate metals, polymers, and ceramics. Ideal for part consolidation, repair, and refurbishment of degraded components, it is suitable for use on the shop floor or on-site.

Features/Specifications:

Gas Type: Air

Gas Pressure: Max 120 PSI

Gas Temperature: RT to 650 °C

Pressure and temperature regulators

Portable and handheld operation

TTEC Versatile Cold Spray System

This low-pressure cold spray system is designed for consolidating brittle powders.

Features/Specifications:

Gas Type: Air, Nitrogen and Helium

Gas Pressure: 40 to 120 PSI

Gas Temperature: RT to 650 °C

Integrated pressure control and thermocouple enabled temperature control

Patented converging-diverging nozzle configuration

Ongoing Research Projects

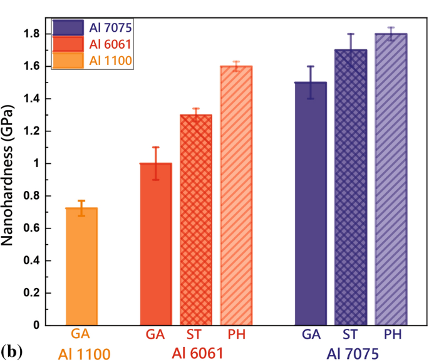

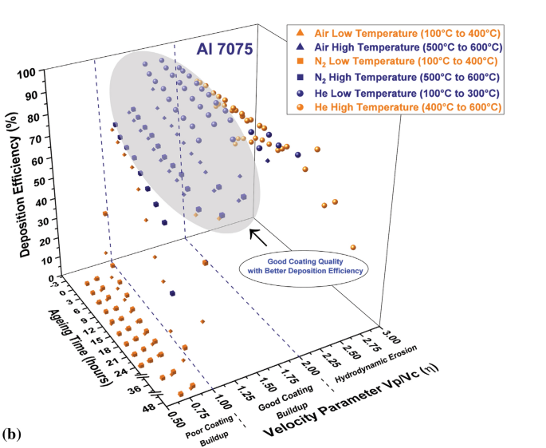

High Strength & Cold Sprayable Powders for Cold Spray

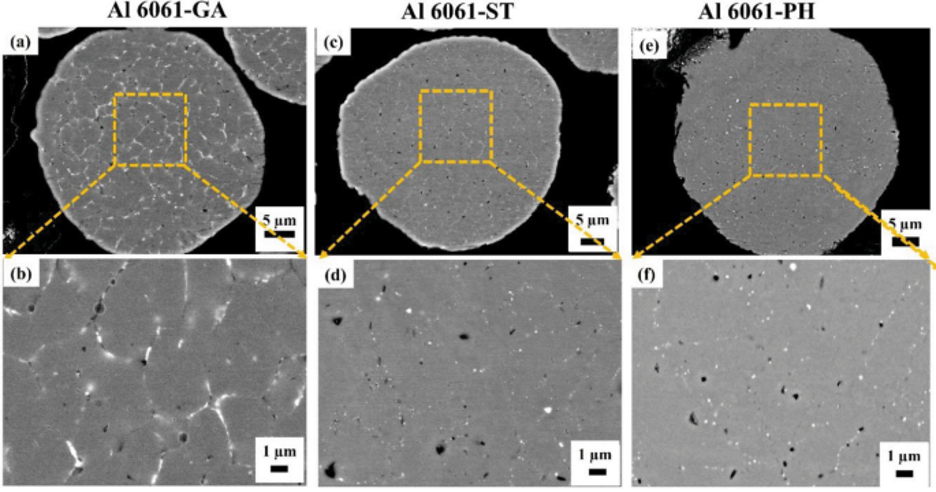

At ColRAD, a primary focus lies in developing customized feedstock powders with high strength and optimal cold sprayability. To achieve this goal, we meticulously tailor the properties of various high-strength aluminum alloy powders, notably Al 6061 and Al 7075, by leveraging their precipitation thermodynamics. Through a nuanced understanding of these materials’ precipitation behaviors, we optimize their characteristics to ensure superior performance in cold spray applications. This strategic approach enhances the powders’ mechanical properties and maximizes their suitability for cold spray processes, empowering ColRAD to deliver advanced solutions tailored to diverse industrial needs.

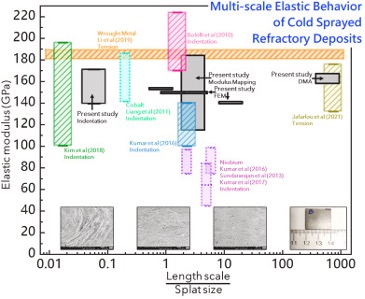

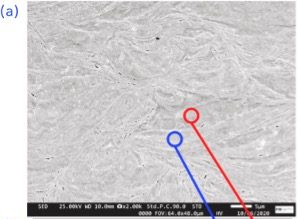

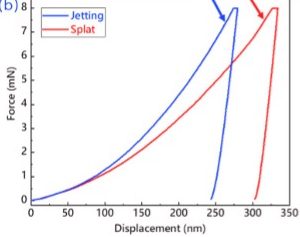

High-Strength Cold Sprayed Deposits

At ColRAD, one of our focus revolves around developing high-strength deposits comprising various aluminum alloys and refractory metals. These deposits exhibit exceptional properties tailored for structural and high-temperature applications. Following the consolidation of these deposits, we employ advanced characterization techniques to meticulously assess their mechanical properties.