Plasma Forming Laboratory

This lab makes use of plasma-based techniques to synthesize:

Tools

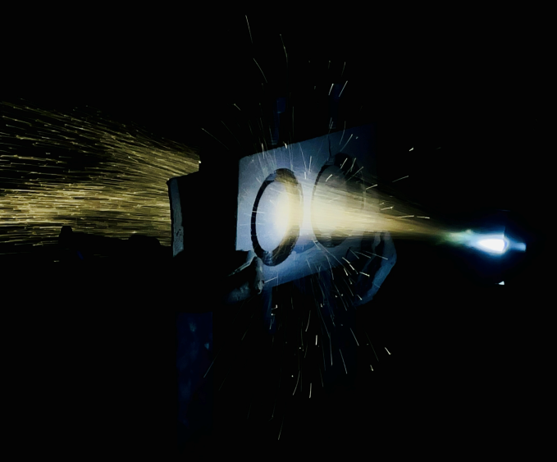

Plasma Torch

The Plasma forming lab utilizes the Plasma Spray Gun Model SG-100, which incorporates both internal and external powder injection capabilities, alongside a localized inert shroud creation capability. Central to the APS system is the plasma torch, which generates the high-temperature plasma flame. Typically, this torch utilizes a gas, often argon, as the primary carrier, undergoing ionization and heating through an electric arc to reach temperatures exceeding 15,000 degrees Celsius. The Plasforming lab integrates robotic systems, including a Fanuc S 100 Robot with RF controller, a CNC turntable, and a three-axis Gantry Robot. For precise control and manipulation of the gun to generate operational pathway for the gun.

Powder Feed System

The Powder Feed System is tasked with introducing coating material, typically fine powder, into the plasma flame. This powder is injected into the plasma stream, where it swiftly liquefies and is propelled toward the substrate. Among the powder feeders utilized are the Powder Feeder Model 1264 and the Thermach AT-1200 Powder Feeder, offering adjustable speeds ranging from 0 to 15 RPM.

Substrate Handling System

The substrate, which may consist of metals, ceramics, or polymers, is situated within the coating chamber. Maintaining precise control over the substrate’s movement is essential to ensure uniform coating thickness and adhesion.

For sample preparation, a Grit Blaster is employed. Additionally, temperature monitoring during the coating process is facilitated by a Raytek Optical Pyrometer with integrated software and PC, capable of monitoring temperatures ranging from -10 to 1200°C. To measure substrate temperature accurately, a 4-channel B-Type Thermocouple (with a temperature range of 0 to 1700°C) and a K-Type Thermocouple (with a range of -200 to 1250°C) are utilized. These thermocouples are connected to an OM-CP-QUADTEMP Data Acquisition System, which interfaces with OM-CP-IFC110 Windows Software for continuous temperature measurement

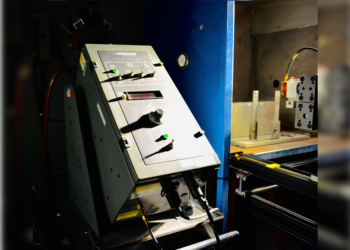

Control System

An advanced control system is essential for regulating various parameters, such as plasma gas flow, powder feed rate, substrate movement, input power, and water-cooling system operation. This ensures the consistency and quality of the coating. The system incorporates the Plasma Power Source Model PS-1000 and the Plasma Control Console Model 3710, which oversee gas flow, input power, and water- cooling system functions.

Coating Materials

Atmospheric plasma spray is compatible with various coating materials, including ceramics, metals, alloys, and composites. This flexibility makes it suitable for diverse applications, from enhancing wear resistance to providing thermal insulation.

Advantages

Versatility : APS can be applied to various substrates, allowing for the coating of complex shapes and intricate surfaces.

High Deposition Rates: The process enables rapid coating deposition, making it time-efficient for large-scale applications.

Diverse Material Compatibility: The technology accommodates a broad spectrum of coating materials, expanding its applicability across different industries.

Applications:

Aerospace: Protective coatings for turbine blades, thermal barrier coatings for engine components.

Energy: Coatings for power generation equipment, such as boiler tubes and gas turbine components. Automotive: Wear-resistant coatings for engine components and cylinders

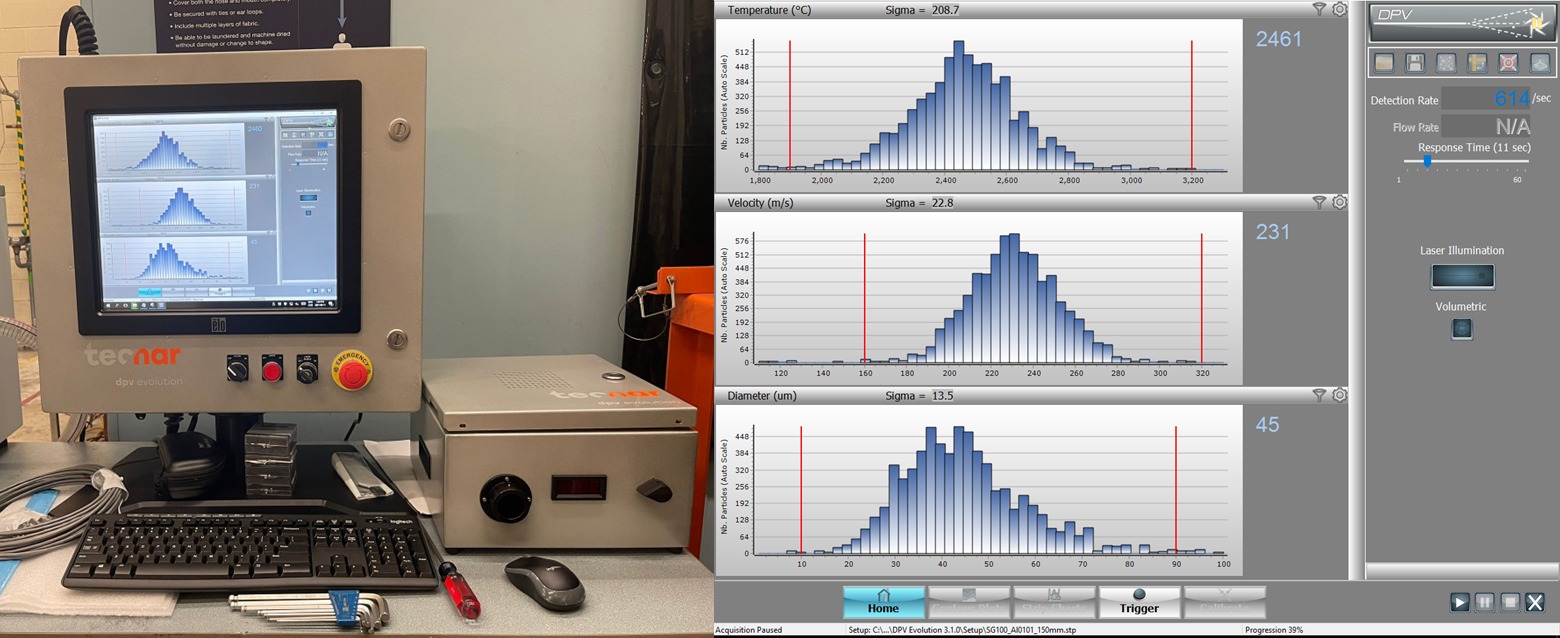

In-Flight Particle Diagnostics

Using advanced In-flight particle diagnostic techniques, such as, DPV-2000 and Accuraspray, this lab is able to measure the precise temperature and velocity of the particles in the spray plume to tailor desired coating characteristics.

Ongoing Research Projects

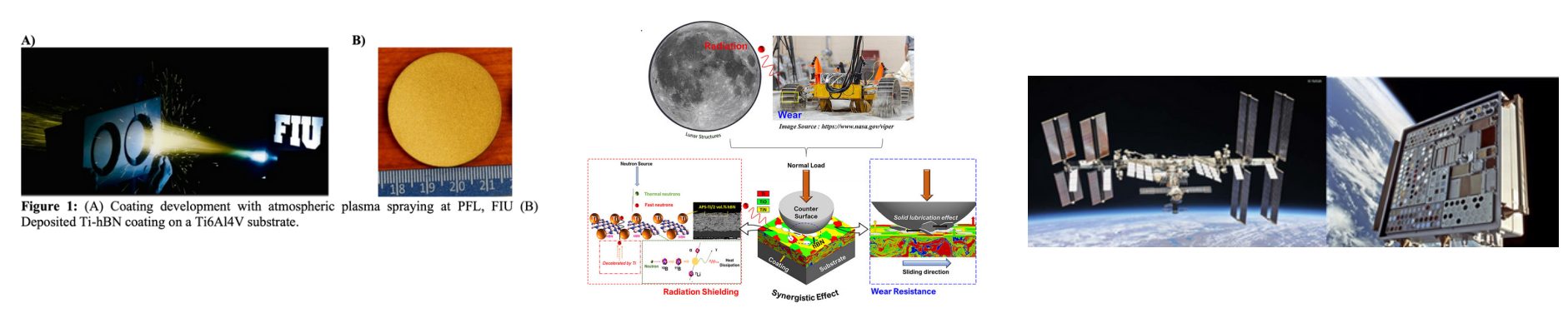

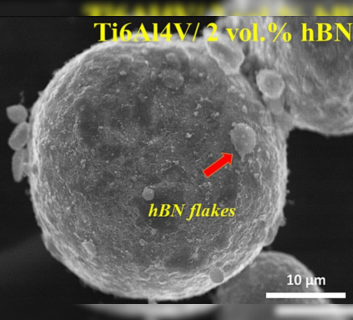

Radiation Shielding Plasma Sprayed Coatings Heads to International Space Station for MISSE-17 Experiments: