Freeze Drying of Foams

Our lab is interested in exploring the multifunctionality that the hierarchical structure of 2D material foams provides to develop lightweight composites with enhanced mechanical strength, thermal properties, and electrical sensing capabilities.

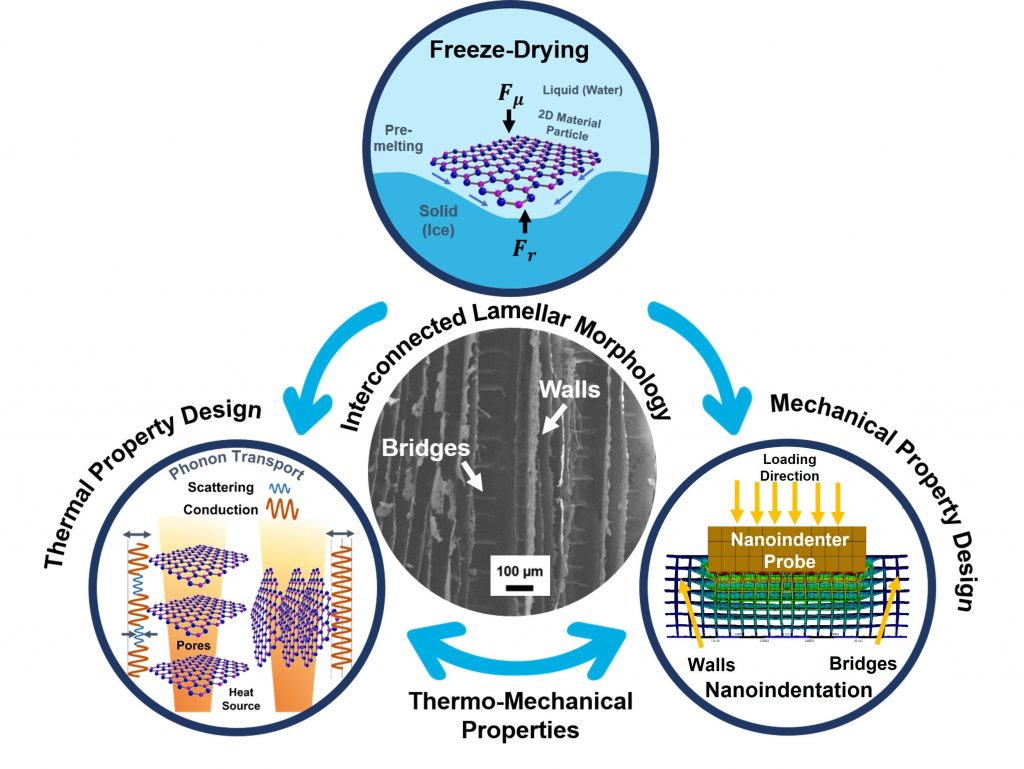

2D materials typically exhibit extraordinarily high thermal and mechanical properties along their basal plane while significantly low properties across their through-plane. A significant challenge with integrating nano-sized 2D fillers in polymer matrices is their high tendency towards agglomeration, which has detrimental effects on the nanocomposite’s properties. 2D material clusters interrupt the phonon conduction path, deteriorating thermal properties. In addition, these agglomerations act as stress concentrators that adversely affect the mechanical properties of the composite.

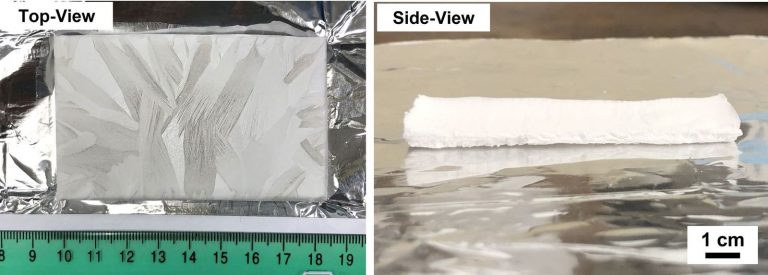

Freeze-Drying is a technique that can overcome agglomeration challenges in 2D material-polymer composites. Freeze-Drying assembles 2D nanomaterials into rigid free-standing three-dimensional (3D) architectures or foams. Pores in these free-standing foams can be infiltrated with polymers to form 2D material–polymer composites with tailorable thermal conductivity and structural stability. The Freeze-Drying process allows the design of the foam with tailored pore size, morphology, and orientation by engineering the processing parameters.

Research efforts at PFL include probing the performance of 2D material foam-based composites in areas of energy, mechanics, deicing, electromagnetic shielding, and health. Studies include the nanoengineering of 2D material foam–polymer interfacial surfaces, and the understanding of fundamental deformation features proving enhanced thermal, electrical and superior load-bearing abilities.