Fabrication and Mechanics of Electrospun Nanofibers

Direct observation of adhesion and mechanical properties of a single poly(lactic-co-glycolic acid) (PLGA) sub-micron fiber using an in-situ nanoindentation technique for tissue engineering

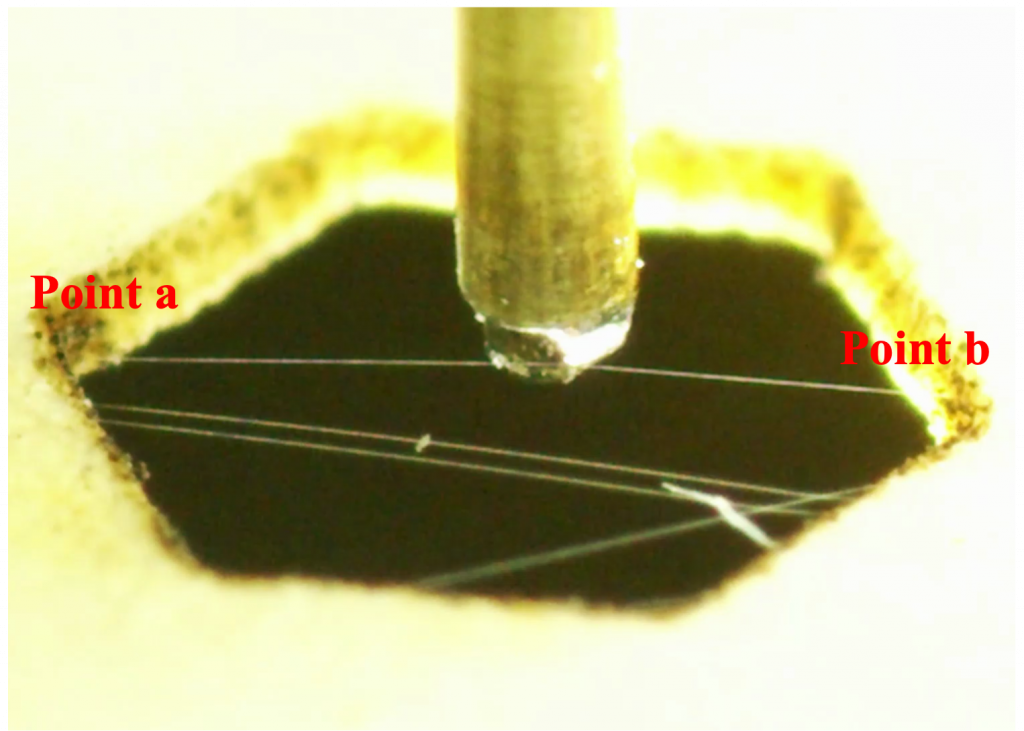

Electrospinning technique is adopted for nano to sub-micron fiber formation, including pure polymer and polymer/functional particle composites. To explore fiber mechanics, we have created two testbeds. The nanoindentation testbed coupled with a high-resolution in situ imaging system is designed to investigate the load-displacement behavior of a single sub-micron poly(lactic-co-glycolic acid) (PLGA) fiber. For example, single PLGA fiber under dry conditions exhibited a maximum force, stiffness, and elastic modulus of ∼2 μN, 1 N/m, and 20 kPa at a condition of maximum displacement of ∼1.5 times its diameter. The adhesion behavior testbed is a specialized approach detects interfacial contact between probe and fiber in real time with extraordinary resolution. The digital image correlation (DIC) technique is adopted to quantify the adhesion force (∼25 μN) between the fiber and the tip. Adhesion force has also been quantified for the fiber after immersing it in phosphate-buffered saline (PBS) to mimic the bioenvironment. A 4-fold increase in adhesion force after PBS treatment was observed due to water penetration and hydrolysis on the fiber’s surface. This research was published in ACS Applied Materials & Interfaces.

Single polymer-nanoparticle composite fiber formation process captured by high-speed camera (150,000 frame per second)