Large-scale Metal 3D Printing by Wire Arc Additive Manufacturing

ML in AM, Adaptive Control System, Realtime Monitoring and 3D Reconstruction

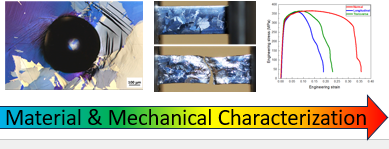

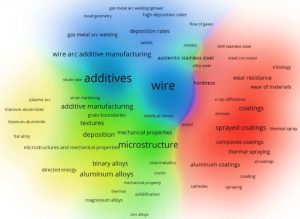

Wire Arc Direct Energy Deposition (W-Arc DED) emerges as a promising strategy for manufacturing parts with intricate and inherent geometries, overcoming challenges posed by traditional subtractive manufacturing processes. Despite its potential, a gap exists in understanding the correlation between microstructure, properties, and the W-Arc DED process. This requires thorough investigations to bridge this knowledge gap, yielding valuable data for standard development and optimization of process parameters. The ultimate goal is to achieve defect-free parts suitable for marine and structural applications, among others.

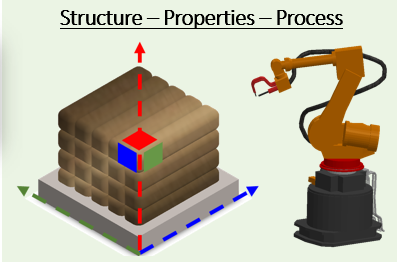

At Florida International University, a diverse group of engineers and scientists has undertaken a comprehensive approach to comprehend W-Arc DED and its impact on material performance. Our efforts are structured around three key pillars

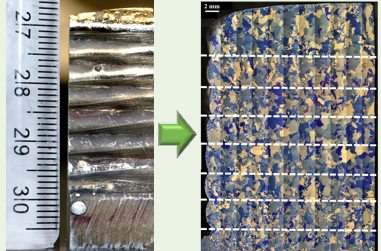

Ongoing investigations have showcased the capability of W-Arc DED to replace traditionally manufactured components. The evidence supports the development of dense deposited microstructures with monolithic characteristics, devoid of lack of fusion, cracks, and featuring negligible porosity. The notable absence of deposited tracks between the overlapped layers signifies a high level of material fusion attainable with W-Arc DED, resulting in more homogeneous mechanical properties. This, in turn, contributes to mitigating the expected anisotropy in this process arising from the complex thermal cycle of the multiple deposited layers.

In collaboration with the Army Research Laboratory (ARL) and other partners, Cold Spray and Rapid Deposition (ColRad) at Florida International University (FIU) are dedicated to advancing novel methods for evaluating W-Arc DED-produced materials. This collaborative effort aims to provide insights that will facilitate the progress of large-scale production for industries such as marine and beyond, unlocking new possibilities for the future.