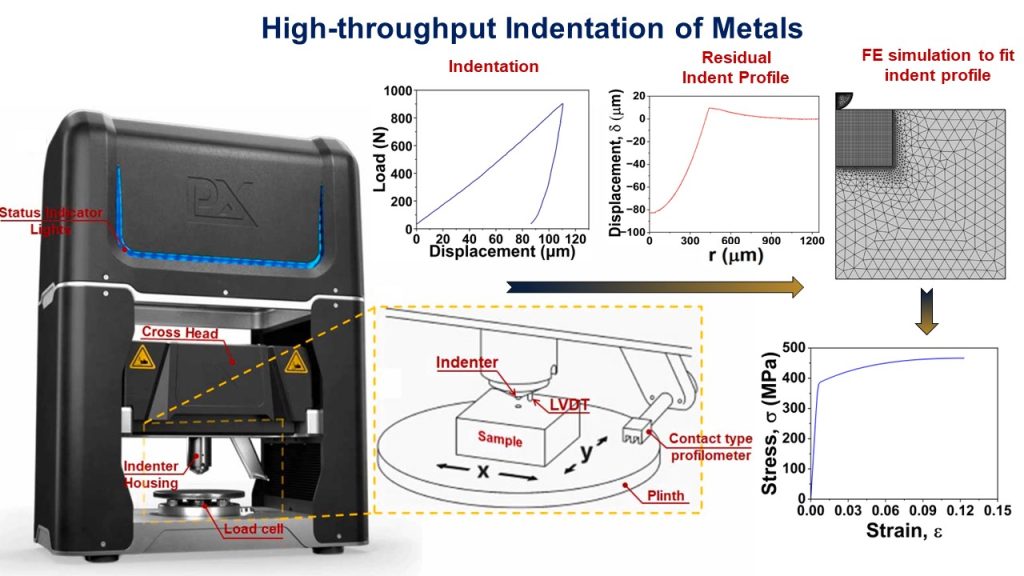

High Throughput Indentation of Metals

Researchers at ColRAD employ an innovative indentation technique known as Profilometry-based Indentation Plastometry (PIP) to advance high-throughput mechanical characterization of materials and offer a new insight in material indentation response. One of the primary advantages of using PIP is its remarkable ability to reduce the required sample size, which, in turn, leads to substantial time and material resource savings. Our current research activities are heavily focused on harnessing the power of PIP for evaluating the mechanical properties of materials produced through additive manufacturing techniques. This cutting-edge research allows us to delve deeper into the intricacies of additively manufactured materials, providing valuable insights for various industries, including aerospace, automotive, and materials science.