High Temperature Tribology Laboratory

The High-Temperature Tribology Lab at FIU is at the forefront of researching friction, wear, and lubrication of interacting surfaces in relative motion, with a specific emphasis on multifunctional materials designed for demanding applications such as abrasion, erosion, and tribocorrosion. The lab specializes in conducting comprehensive friction and wear testing of materials under elevated temperatures, exploring their unique properties and behaviors to address challenges across diverse industries including automotive, aerospace, and additive manufacturing.

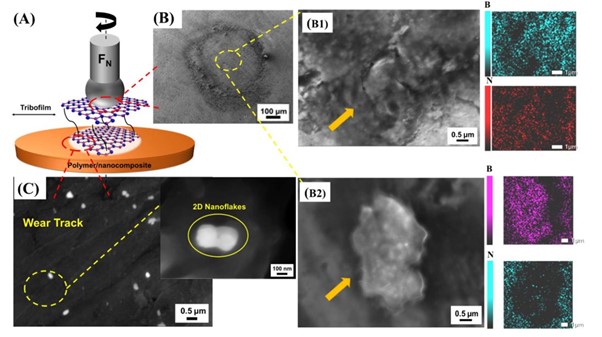

Tribology research encompasses a wide range of materials, including newly developed composite materials, solid lubricants infused into polymer and metal composites, and wear-resistant coatings tailored for lunar structures. By leveraging the state-of-the-art high-temperature tribology facility, researchers investigate the performance of these materials, aiming to enhance their durability and functionality under extreme conditions. Additionally, the lab is actively engaged in studying the tribocorrosion effects on components manufactured through additive processes, contributing to the development of robust solutions for additive manufacturing applications.

Tools

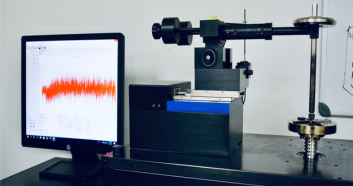

High Temperature Tribometer

The Optical Profilometer represents a cutting-edge solution in the field of surface metrology, offering researchers, engineers, and manufacturers unparalleled precision and versatility in characterizing surface topography.

- Load System: Tribometers apply controlled loads to simulate real-world conditions.

- Motion System: The motion mechanism, often rotational / linear, imitates the sliding or rolling movements

encountered in practical applications. - Sensor Systems: These systems measure parameters like frictional forces, wear rates, and temperature changes during testing.

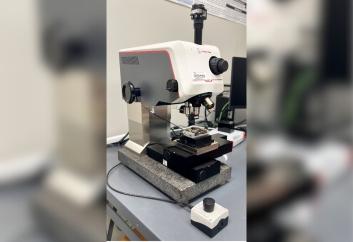

Optical Profilometer

The Optical Profilometer represents a cutting-edge solution in the field of surface metrology, offering researchers,

engineers, and manufacturers unparalleled precision and versatility in characterizing surface topography.

- Non-Contact Profilometry: The Nanovea Optical Profilometer employs non-contact techniques, ensuring that delicate and sensitive surfaces remain undisturbed during measurements. This feature is crucial for accurately characterizing fragile materials and intricate structures.

- High-Resolution Imaging: With advanced optics and imaging sensors, the system delivers high-resolution surface imaging, capturing details at the nanoscale. This capability allows for a thorough examination of surface features, defects, and roughness.

- 3D Profilometry: The instrument excels in 3D surface profiling, providing a comprehensive understanding of surface morphology. Researchers can visualize and analyze complex structures with precision, enabling a detailed assessment of surfaces in three dimensions.

Revetest Scratch Tester

The Revetest Scratch Tester is a versatile tool designed for mesoscale tribology characterization, catering to polymers, metals, and ceramics. Equipped with load frames ranging from 1 to 200 N and various indenters, it conducts high-throughput scratch tests. Its applications span characterizing mechanical surface properties of thin films and coatings, such as adhesion, fracture, wear, and deformation. Key outputs include frictional force, coefficient of friction, residual depth, penetration depth, and wear data quantification, with precision boosted by the real-time acquisition of acoustic emission data and panoramic wear scar visualization.

Ongoing Research Projects

Unveiling High-Temperature Friction and Wear Characteristics in Advanced Structural Materials

Advancements in science necessitate the development of novel structural materials capable of enduring extreme temperatures across diverse fluid and environmental settings. Understanding the friction and wear characteristics of these materials at elevated temperatures holds paramount significance for the efficient operation of both mobile and stationary machine components.

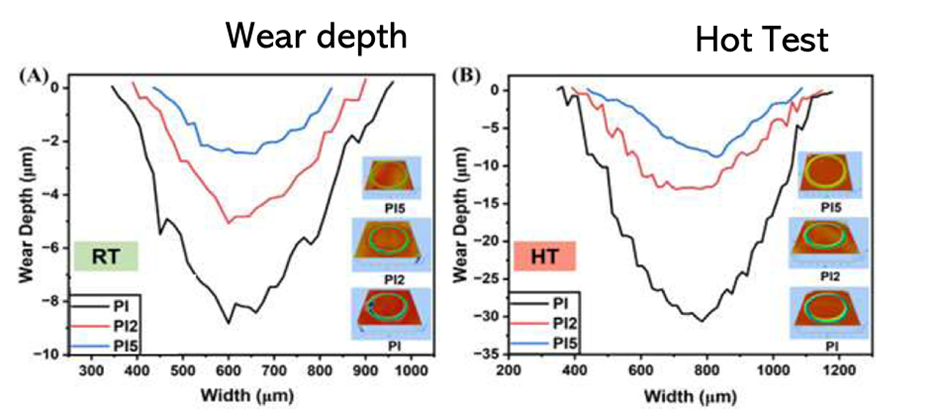

The effectiveness of materials in components experiencing high-temperature friction is closely intertwined with their mechanical performance in elevated thermal conditions. The tribological behavior of machine parts, instruments, and tools in contact is of utmost importance. Ongoing research at Florida Internanional University focuses on scrutinizing the friction and wear tendencies of diverse materials such as metals, ceramics, composites, and polymers when exposed to temperatures ranging from 150 to 800°C. FIU employs ball-on-disk rotational and reciprocating tribology modules to test and evaluate the varying wear properties for numerous applications.

- Wear Resistant Ti/hBN coatings for lunar structural components

- Polymer-hBN high-temperature composites for aerospace components

- Tribo corrosion of Cp-Ti Wire Direct Energy Deposition components